How To Install Double French Doors

Replace an overhead door with pre-hung double panels.

Past Matt Weber

To increase the finished living space in a split-level dwelling, nosotros removed a garage door and replaced it with a double door to remodel the interior into a family room. This insulated fiberglass door was smaller than the garage door opening, which required us to frame the new opening. Replacing a door unremarkably presents the challenge of installing the door snugly and securely into the existing rough opening. In this instance, however, we built the crude opening to fit the door. Here's how we tackled the project.

Non-load-bearing Framing

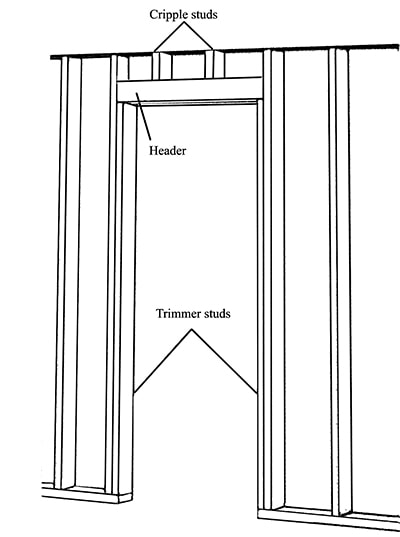

It'southward important to notation that we framed this door equally a not-load-bearing wall. Most exterior doors require a load-bearing header installed directly higher up the jamb. Headers are structural framing members made from doubled 2x lumber that bridge the rough opening of a door or window to distribute the overhead weight that would otherwise fall on the missing studs. The size of the header depends on the span of the opening and whether or not it is a load-begetting wall.

In this instance, we removed the existing garage door, which had already been constructed with a substantial header, and left the structural framing in identify to behave the load. We then constructed a secondary wall merely inside the framed opening to house the new double door. Because the existing header satisfied the load-begetting requirements, the secondary wall serves only to define the crude opening, enclose the sides of the door, and provide a nailing surface for wallboard and capsule. Since the new, secondary header was not a load-bearing component, we congenital it with doubled 2×4 lumber.

Determining Placement

Offset step was to accept a few measurements to center the double door in the opening. We calculated the proximity of the new wall to the existing frame by accounting for the thickness of the capsule that would be installed betwixt them. We then snapped a chalk line on the floor to guide placement of the door jamb and new wall.

At least two people are required to move a double door. Placing the pre-hung door and jamb into the opening, however, enabled us to easily make accurate measurements and layout marks to build the surrounding frame.

Sometimes when installing a replacement door the jamb is a lilliputian too pocket-size for the opening, requiring shims or trim-boards for aligning. When framing around a door, though, you can construct the frame with as tight a surround equally you desire—just exit enough fudge room to let maneuvering the door into the rough opening. Building around the door also enables you to eliminate the out-of-square framing errors associated with the business firm settling (or poor carpentry). Always brand sure to build the crude opening plumb, foursquare and true for doors and windows, ensuring no studs are bowed.

Building the Frame

Nosotros constructed the wall with a typical sill plate, bottom plate, and studs spaced 16 inches on middle. Nosotros anchored the sill and installed a top plate with two studs on each side of the door. We and so removed the door and fix it bated while nosotros continued construction of the wall.

Installing sheets of rigid foam insulation with a moisture bulwark helps to weather-proof the building envelope of the new frame. We nailed the foam sheets over the confront of the frame and cut information technology to fit. Apply flashing tape to seal the edges of the rigid cream to the surrounding frame. Employ a sill plan to ensure wet protection at the bottom of the door jamb.

Installation

We applied beads of sealant forth the bottom of the opening, including the seams at the lower corners, and inserted the pre-hung door frame from the exterior of the business firm. Don't slide the door in place, however, which messes up the sealant beads. It's best to tilt information technology into position and and then brand adjustments.

Refer to the manufacturer'southward instructions for specific steps to install your door, because methods may vary among models. In general y'all should center the jamb in the door frame, then drive one 10d cease blast or iii-inch screw through the mid-bespeak of each hinge jamb into the framing studs. The nails or screws are used to hold the door in identify while yous plumb and square the jamb, using shims if necessary. Place the shims at the swivel locations betwixt the jamb and the studs. Apply shims in other locations every bit needed to square the opening. Check for square by measuring the diagonals of the jamb in an Ten design (corner to corner) to ostend they match.

On double doors, it's of import to make sure the door panels are even across the top and bottom and that the reveal between them is fifty-fifty.

Pre-hung doors often include long screws that insert into the open up holes of the door'southward hinge(due south) once the door is in terminal position. When driving the screws, make sure non to bow the sides of the door jamb.

After checking to brand sure the door opens and closes properly, keep fastening the jamb to the frame with 10d finish nails or predrilled 3-inch screws.

Finishing Touches

As with whatever new door installation, the edges and air gaps should be insulated and sealed with spray cream and caulk.

Refer to the manufacturer's instructions for specific steps to install your door. They oftentimes come with ong hinge screws that are driven through the hinge locations of the jamb, through shims and into the stud framing. Brand certain non to bow the sides of the door frame.

Pro Tip: Insert a foam backer rod effectually the brick-mold of the door equally deep as it will go to provide at to the lowest degree 3/8-inch clearance from the surrounding siding. Caulk over the backer rod with a bead of quality exterior-grade sealant, and tool the caulk bead smooth. This method creates a flexible sealant line around the door that is capable of expanding and contracting.

For this projection, we finished the outside wall with cement siding, trim boards and a new glaze of matching pigment. Ii decorative outdoor wall fixtures wired into the new wall gave the new double doors a finishing touch that greatly added to the curb entreatment of the home.

Source: https://extremehowto.com/double-door-garage-conversion/

Posted by: hamiltondageter.blogspot.com

0 Response to "How To Install Double French Doors"

Post a Comment